Well Services

- Home

- Our Services

- Well Services

Well Services

Once a well is completed, our robust suite of wireline equipment allows for cost-efficient and reliable intervention work from the truck to the software to the BOP stack. From there, production begins. Whether on land or offshore, our highly-engineered equipment helps lift, pump, flow and separate oil, gas, water and sand streams on the surface or even subsea. Our variety of composite piping and structures helps to connect and carry product in even the most corrosive environments.

We are here with our new technologies engineered by NOV to solve the latest oilfield problems, and to help our clients achieve lasting success.

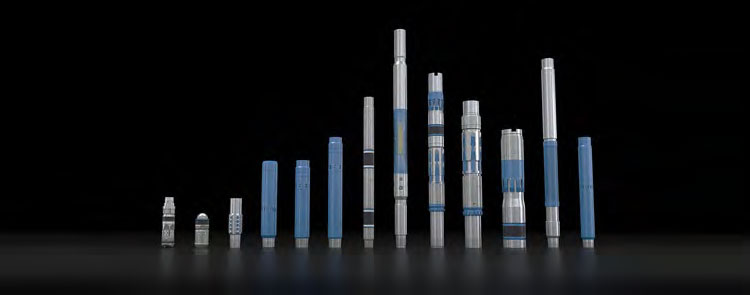

E-Line/Slickline Pressure Control String

Slickline Tools and Flow Control

Slickline Tools:

- Standard Toolstring

- Running, Pulling, Shifting and Positing Tools

- Fishing Tools

- Special Application

- Flow Control Equipment

- NOV Series Locks and Plugs

- OTIS Style Locks and Equalising Assemblies

- Completion Accessories

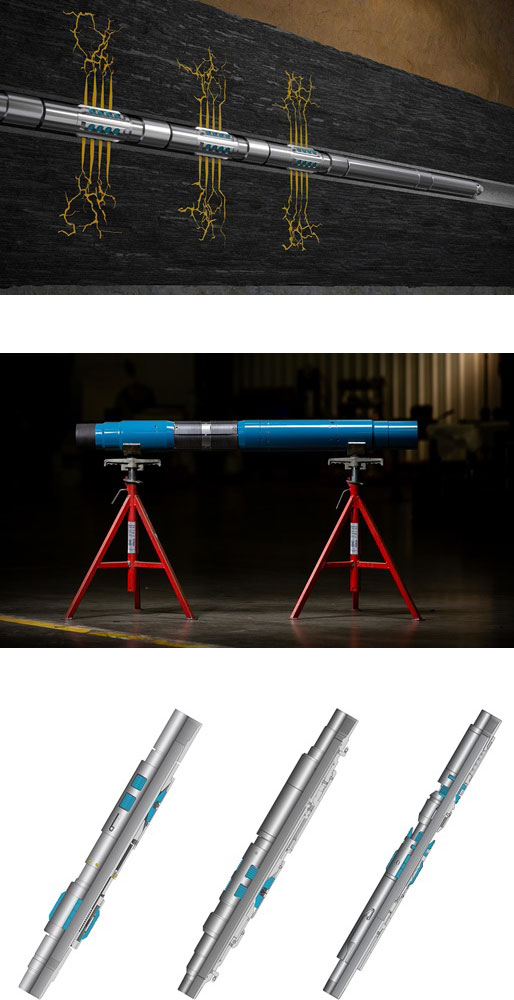

Well Completion

Multistage Completions:

We offer a variety of multistage fracturing completion from plug-and-perf systems and ball-drop systems to coiled tubing systems.

Well Construction:

We provide reliable completion products including liner hanger, Liner Packer and PBRs, liner hanger packers, liner cementing and accessories, and liner running and service tools to ensure your well integrity.

Downhole Monitoring:

Gathering and understanding dynamic data recorded during well operations are critical to success.

We offer our i-Con, i-Trace, and MaxTrace monitoring tools.

ReAct systems:

We offer remote signaling capabilities to downhole valves and sleeves with our ReAct product line, which includes circulation valves, electronic liner shoes, cleanout valves, tracer valves, inflow valves, up to tubing filler subs.

Intervention systems:

We offer various coiled tubing, wireline, and workover completion tools that can be customized to your well.

Conventional completion:

To support your onshore and offshore projects, we offer a growing suite of conventional completion solutions from production packers to subsurface safety valves and flow control systems.

Dissolvable products:

Our dissolvable balls and plugs can retain structural integrity under high temperatures and differential pressures for a specific range of time, dependent upon fluid conditions in the wellbore, before dissolving.

GSP II Liner Hanger

Features & Benefits

- Non-weld design, one-piece body with premium threads.

- Slips are fully recessed and pocketed into a special profile at the rotating body to prevent from premature setting during running.

- Slips and cone are designed to minimize casing stress.

- Slips are designed and tested to hang inside a large range of casing weights.

- All hydraulic seals remain stationary during rotation of the liner.

- Improved seal stack in the hydraulic cylinder; HP/HT seals.

- Capable of hanging long, heavy liners with enhanced hanging capacity.

- Large annular flow area in set and unset position.

- Lock of slips prevents premature setting during running.

- Rotating/non-rotating (optional).

Materials

- L80, T95, P110, Q125, 22Cr 125 ksi. Other materials on request

Thread connections

- Standard VAM® TOP/VAM® 21 or on customer’s request

Integrated Liner Hanger Packer

SUREST Liner Hanger Packer

Features and benefits

- Hydraulic set as standard; mechanical set available

- Eliminates potential leak path between hanger and packer Fully pocketed slips for running in challenging conditions

- Non-rotating and rotating during cementing options available

- 10,000 psi tested rating in all sizes

- Integrated packoff nipple

- Large annular flow area in set and unset positions

- Internal body lock ring positively locks in applied setting force to packing element

- Capable of hanging long, heavy liners with enhanced hanging capacity and multi-cone options

Thread Connections

- Standard VAM 21/VAM TOP

- Other premium connections available upon request

- BTC, LTC

Materials

- L80, L80 13Cr, T95, C110, P110, Q125, SM2535/VM28

- Other materials available upon request